A Journey Through the World of Fastening Systems

Introduction

Embarking on a journey through the intricate and indispensable realm of

fastening systems unveils a fascinating tapestry of precision engineering,

structural integrity, and industrial efficiency. At the core of this intricate

web are the unsung heroes – bolts and nuts. In the grand symphony of

construction, manufacturing, and engineering, these tiny yet mighty components

play a pivotal role, holding together the fabric of countless structures and

machines.

As we navigate

through the diverse landscapes of industries, the significance of reliable

fasteners becomes abundantly clear. Bolts and nuts serve as the unsung

guardians, ensuring the stability and durability of structures ranging from

towering skyscrapers to intricate machinery. The success of any project,

whether colossal or minute, hinges on the quality and precision of these

connectors. It's a world where every turn of a bolt and every tightening of a

nut contributes to the robustness of the entire system.

In this

exploration, our focus zooms in on the heartbeat of this vast ecosystem – bolts

and nuts suppliers. These suppliers form the backbone of the fastening

industry, providing the lifeblood that keeps the wheels of construction and

manufacturing turning seamlessly. Their role is not merely transactional; it is

a partnership that extends beyond the mere exchange of goods. Bolts and nuts

suppliers become architects of connectivity, threading together the aspirations

of builders and innovators.

As we delve deeper

into the dynamics of this domain, we will unravel the innovations, challenges,

and advancements that shape the narrative of bolts and nuts suppliers. From

traditional craftsmanship to cutting-edge technologies, this journey promises a

comprehensive understanding of an industry that silently supports the

structures upon which our modern world stands. Join us as we embark on 'A

Journey Through the World of Fastening Systems,' where bolts and nuts emerge as

the unsung heroes, and their suppliers play a crucial role in shaping the

future of construction and engineering.

Understanding the Basics of Fastening Systems

Key Points to Explore:

·

The Crucial Role of Bolts and Nuts: In the expansive

landscape of construction and manufacturing, bolts and nuts play a pivotal role

in ensuring the structural integrity of buildings and machinery.

·

Precision Engineering in Action: Fastening systems

are a testament to precision engineering, where the snug fit of bolts into nuts

determines the reliability of the entire assembly.

·

Diverse Applications: From the towering structures of urban

landscapes to the intricate machinery of manufacturing units, fasteners find

application in a myriad of industries, holding together the diverse elements of

our modern world.

·

Bolts and Nuts Suppliers as Pillars of Support: Beyond the physical

components, understanding the basics involves recognizing the significance of

bolts and nuts suppliers. These suppliers are the lifelines of the fastening

industry, providing the necessary linkages for seamless construction and

manufacturing processes.

The Foundation: Bolts and Nuts

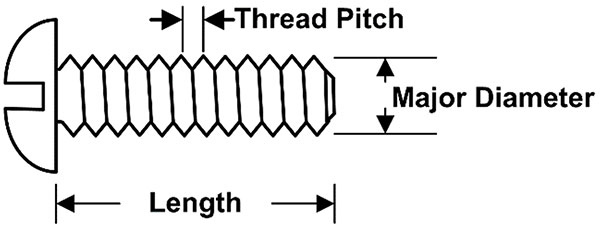

Bolts and nuts, often referred to as the fundamental elements of

mechanical joints, are threaded fasteners designed to bind two or more

components securely. Bolts are typically cylindrical rods with an external

thread, while nuts are internally threaded components that mate with the bolts.

This seemingly simple combination forms the basis for an extensive array of

applications, from assembling furniture to constructing towering skyscrapers.

The Role of Material in Fastening Systems

One of the key factors determining the effectiveness of a fastening

system is the material from which bolts and nuts are made. Different projects

demand different materials, and suppliers play a pivotal role in providing a

diverse range. From standard carbon steel for general applications to

corrosion-resistant stainless steel for harsh environments, the choice of material

is a critical decision that can influence the longevity and performance of a

structure.

Navigating the Market: Bolts and Nuts Suppliers

In the intricate landscape of construction and manufacturing,

where every joint is a connection of significance, bolts and nuts emerge as the

linchpins holding the structures together. As we embark on a journey of

exploration, our focus turns towards the architects of connectivity - the bolts

and nuts suppliers. 'Navigating the Market: Bolts and Nuts Suppliers' is an

expedition into the heartbeat of the fastening industry, unraveling the

dynamics that shape the market and the indispensable role played by these

suppliers.

Key Insights to Uncover:

1.

Supply Chain Dynamics: The market for bolts and nuts is a

complex tapestry of demand and supply. Understanding the intricacies of this

market requires navigating through the supply chain dynamics orchestrated by

suppliers who act as crucial conduits.

2.

Innovation and Variety: Bolts and nuts suppliers are not mere

purveyors; they are the driving force behind innovation. Exploring their

contributions unveils a world of diverse materials, coatings, and designs that

cater to the evolving needs of industries.

3.

Market Trends and Challenges: A comprehensive

exploration involves navigating through the ever-changing market trends and

challenges. Bolts and nuts suppliers, as market custodians, respond to these

shifts, shaping the trajectory of the industry.

4.

Partnership in Progress: Beyond transactions, bolts and nuts

suppliers are partners in progress for builders, manufacturers, and engineers.

Understanding their role goes beyond the exchange of goods; it's about

fostering collaborations that contribute to the success of projects.

The Importance of Reliable Suppliers

In the realm of construction and manufacturing, the reliability of

fastening systems is non-negotiable. This places a significant emphasis on the

suppliers who source and provide bolts and nuts. Choosing the right supplier

ensures the quality, consistency, and compliance of these critical components

with industry standards. Whether for a small-scale DIY project or a large-scale

infrastructure endeavor, the selection of a reputable supplier can make or

break the success of the entire venture.

Key Characteristics of Reputable Bolts and Nuts Suppliers

1.

Quality Certification and Compliance: A reliable

supplier must adhere to industry standards and hold certifications attesting to

the quality of their products. ISO certifications, for example, signify that

the supplier's manufacturing processes meet international benchmarks.

2.

Product Range and Customization: The ability to offer a diverse range of bolts and nuts tailored to

specific project requirements sets exceptional suppliers apart. Customization

options, such as different sizes, coatings, and materials, allow for

flexibility in meeting the unique needs of each project.

3.

Supply Chain Efficiency: Timely delivery is

crucial in construction and manufacturing projects. Suppliers with streamlined

supply chains and efficient logistics ensure that the required components are

delivered when and where they are needed, preventing costly delays.

Spotlight on Bolts and Nuts Suppliers: A Closer Look

As a leading player in the industry, Supplier A has garnered a

reputation for consistently delivering high-quality bolts and nuts. With ISO

9001 certification, they adhere to stringent quality control measures. Their

product range spans various materials, including carbon steel, alloy steel, and

stainless steel, catering to a wide spectrum of applications. The efficiency of

their supply chain ensures that clients receive their orders promptly, making

them a reliable choice for projects of all sizes.

Specializing in customized solutions, Supplier B stands out for its

ability to meet unique project specifications. They offer an extensive range of

coatings, from zinc plating to hot-dip galvanizing, providing options for

corrosion resistance tailored to specific environmental conditions. With a

commitment to sustainability, Supplier B also emphasizes the use of

eco-friendly materials, catering to the growing demand for environmentally

conscious construction practices.

The Evolution of Bolts and Nuts: Innovations in Fastening Systems

In the ever-evolving realm of construction and manufacturing,

the unsung heroes – bolts and nuts – have been silently advancing, shaping the

very foundation of structural integrity. 'The Evolution of Bolts and Nuts:

Innovations in Fastening Systems' invites us on a journey through time, where

the simple act of joining two components has metamorphosed into a dynamic arena

of technological marvels and engineering ingenuity.

Exploring the Landscape of Advancements:

1.

Technological Prowess: The journey begins by tracing the path

of technological advancements that have revolutionized the manufacturing and

design of bolts and nuts. From traditional craftsmanship to precision

engineering, technology has played a pivotal role in transforming these

fasteners.

2.

Materials and Coatings: Dive into the realm of materials

science as we unravel the innovative use of alloys, composites, and specialized

coatings. The evolution of materials has not only enhanced the strength and

durability of bolts and nuts but has also paved the way for applications in

diverse industries.

3.

Customization and Specialization: The evolution is not

just about standardization but embraces customization. Fasteners are now

tailored to meet the specific demands of unique projects, allowing for a more

efficient and effective integration into diverse structures and systems.

4.

Sustainability in Fastening: As environmental

consciousness rises, innovations in bolts and nuts extend to sustainable

practices. From recyclable materials to energy-efficient manufacturing

processes, the evolution reflects a commitment to a greener and more

sustainable future.

Advancements in Design and Technology

While the basic principle of bolts and nuts remains unchanged,

technological advancements have led to innovations in their design and functionality.

High-strength bolts, for instance, have become a staple in applications

requiring superior load-bearing capabilities. Additionally, the advent of

electronic sensors embedded in fasteners has revolutionized the monitoring of

structural integrity, providing real-time data on stress, tension, and

temperature.

Sustainable Fastening Systems

As the world grapples with environmental concerns, the construction and

manufacturing industries are actively seeking sustainable practices. This

includes the development of eco-friendly fastening systems. Suppliers are

responding to this demand by offering bolts and nuts made from recycled

materials, as well as exploring alternative materials with a lower

environmental impact. The push for sustainability is reshaping the landscape of

fastening systems, influencing both design and manufacturing processes.

Challenges in the World of Bolts and Nuts

In the intricate landscape of fastening systems, bolts and nuts

stand as essential components, binding structures together with unyielding

strength. However, beneath the surface of this critical industry lie challenges

that demand a closer examination. 'Challenges in the World of Bolts and Nuts'

beckons us to delve into the complexities that suppliers, manufacturers, and end-users

face, shaping the narrative of this indispensable sector.

Exploring the Complexities:

1.

Quality Assurance Concerns: The integrity of any

structure hinges on the quality of its fasteners. Challenges in maintaining

consistent quality standards across various production processes and materials

demand a vigilant approach from bolts and nuts suppliers.

2.

Diversity in Applications: Bolts and nuts find

applications across a multitude of industries, each with its unique demands.

Addressing diverse needs while ensuring standardization poses a continuous

challenge for suppliers catering to a wide range of sectors.

3.

Technological Advancements: While technological

innovations bring progress, they also introduce challenges. The fast-paced

evolution in materials and manufacturing technologies demands adaptability from

suppliers to stay abreast of the latest developments.

4.

Market Volatility: The market for bolts and nuts is susceptible to economic

shifts, impacting both demand and pricing. Suppliers navigate through these

fluctuations, striving to maintain stability in an environment prone to

unpredictability.

Counterfeiting and Quality Concerns

The ubiquity of bolts and nuts in construction has unfortunately given

rise to a market plagued by counterfeiting. Substandard and counterfeit

fasteners pose serious risks, compromising the structural integrity of

projects. Reputable suppliers play a crucial role in mitigating this challenge

by implementing stringent quality control measures, providing genuine

certifications, and ensuring traceability throughout the supply chain.

Price Fluctuations and Economic Factors

The cost of raw materials, especially metals like steel, directly

impacts the pricing of bolts and nuts. Economic fluctuations and global events

can lead to unpredictable price variations, posing challenges for both

suppliers and consumers. Navigating these economic factors requires strategic

planning and collaboration between suppliers and project stakeholders to

mitigate the impact on project budgets.

Read Also: Bolting Through Time: A Historical Perspective on Carriage Bolts

Future Prospects: Trends and Outlook

Industry 4.0 Integration

The integration of Industry 4.0 principles into manufacturing processes is

influencing the fastening systems landscape. Smart factories equipped with

advanced automation, data analytics, and artificial intelligence are enhancing

the efficiency and precision of bolt and nut production. This digital

transformation is expected to streamline supply chains, reduce lead times, and

further improve the overall quality of fastening systems.

Continued Emphasis on Sustainability

The trend toward sustainability is likely to intensify, with suppliers

investing in research and development to create fastening systems with minimal

environmental impact. Innovations in recyclable materials, eco-friendly

coatings, and circular economy practices will shape the future of bolts and

nuts, aligning with the broader goals of sustainable development.

Conclusion

As we conclude our journey through the world of fastening systems, the

significance of bolts and nuts and their suppliers cannot be overstated. From

the foundational role they play in construction to the ongoing evolution driven

by technological advancements and sustainability initiatives, bolts and nuts

are integral to the fabric of our built environment.

Choosing the right

bolts and nuts suppliers and Hex Nuts Manufacturers are decision that ripples through the entire lifespan

of a project. The reliability, quality, and innovation offered by suppliers

contribute not only to the structural integrity of buildings and machinery but

also to the broader goals of sustainability and responsible manufacturing.

In this fast-paced

and ever-evolving landscape, the journey of bolts and nuts continues,

intertwined with the progress of industries and the aspirations of a

sustainable future.

Comments

Post a Comment