Bolting Through Time: A Historical Perspective on Carriage Bolts

Introduction

In the intricate tapestry of construction and machinery, bolts

serve as the unsung heroes, holding together the very foundations of our

structures and innovations. Among this vast array of fasteners, the carriage

bolt stands as a testament to the marriage of form and function across the

centuries. "Bolting Through Time: A Historical Perspective on Carriage

Bolts" invites us to embark on a fascinating journey, delving into the origins,

evolution, and enduring relevance of this unique and time-tested fastener.

As we unravel the historical narrative of carriage bolts, we

unearth their humble beginnings in the 19th century, designed with ingenuity to

meet the specific challenges faced by the transportation industry of that era.

The distinct characteristics of rounded heads, square necks, and smooth shanks

not only addressed those challenges in horse-drawn carriages but also laid the

foundation for a versatile fastener that would transcend its original purpose.

This exploration takes us through the Industrial Revolution,

where carriage bolts evolved to become pivotal components in the rapidly

changing landscapes of construction and manufacturing. The standardization of

these bolts, driven by mass production techniques, marked a crucial turning

point, solidifying their position as reliable and universal fastening

solutions.

Fast forward to the modern era, and we witness the adaptability

of carriage bolts in the face of technological advancements. Materials have

evolved, coatings provide enhanced protection, and specialized designs cater to

a myriad of applications. Furthermore, our journey extends beyond the bolts

themselves to the suppliers who play a crucial role in providing quality products

that stand the test of time.

As we embark on this historical exploration, "Bolting

Through Time" promises to unveil the fascinating story behind the

unassuming carriage bolt, shedding light on its historical significance and its

enduring role in shaping the landscapes of construction, machinery, and

industrial progress. Join us in this riveting journey through time, where each

turn of the bolt opens a portal to the rich history woven into the very fabric

of our built environment.

The Birth of Carriage Bolts: 19th Century Ingenuity

In the annals of fastener history, the 19th century emerges

as a crucible of ingenuity, giving birth to a remarkable engineering marvel –

the carriage bolt. As we delve into "The Birth of Carriage Bolts: 19th

Century Ingenuity," we unveil the origins of this distinctive bolt.

Crafted with foresight to meet the challenges of the transportation industry,

the carriage bolt's rounded head, square neck, and smooth shank were

ingeniously designed for the wooden components of horse-drawn carriages. This

exploration takes us back to a transformative era, where the seeds of

innovation sown in the 1800s continue to bear fruit, securing the foundations

of our modern world.

Origins and Design

The carriage bolt, also known as a coach bolt or round head square neck

bolt, emerged during the early 19th century. Its design was a stroke of

engineering brilliance, conceived to address specific challenges faced by the

transportation industry of the time. Carriage bolts feature a rounded head, a square

neck just beneath it, and a smooth, cylindrical shank extending from the neck.

The square neck ensures that the bolt remains securely in place as it is

tightened, preventing it from rotating during installation.

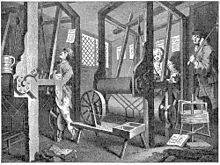

Application in Horse-Drawn Carriages

The initial application of carriage bolts was in the construction of

horse-drawn carriages, which were a primary mode of transportation in the 19th

century. The unique design of these bolts made them particularly well-suited

for the wooden components of carriages, providing stability and security. The

smooth shank prevented the bolts from damaging the wood, while the square neck

ensured a snug fit, enhancing the overall structural integrity of the carriage.

Evolution Through the Ages: Carriage Bolts in the Industrial Revolution

Industrial Applications

The versatility of carriage bolts became evident as they found

applications beyond the realm of carriages. Industries embraced these bolts for

their durability and ease of use, incorporating them into the construction of

machinery, railroad infrastructure, and even early automobiles. The unique

combination of the rounded head and square neck proved invaluable in providing

stability and preventing unwanted rotation.

Mass Production and Standardization

With the advent of mass production techniques, carriage bolts became one

of the first standardized fasteners. Manufacturers could now produce large

quantities of identical bolts, ensuring consistency and interchangeability.

This standardization facilitated the widespread adoption of carriage bolts

across various industries, solidifying their status as a reliable and universal

fastening solution.

Carriage Bolts in the Modern Era: Adapting to Changing Times

- Material Advancements: From traditional iron to contemporary steel and alloys, carriage bolts have embraced technological progress.

- Protective Coatings: Modern variants boast coatings like zinc plating, enhancing durability and resistance against corrosion.

- Specialized Designs: Varied adaptations cater to unique applications, featuring flanges for increased load-bearing capacity and serrations to prevent loosening.

Embarking on this

exploration unveils how carriage bolts, once confined to carriage construction,

have seamlessly adapted, becoming stalwarts in diverse industries, showcasing

their ability to withstand the test of time and innovation.

Materials and Coatings

As technology advanced, so did the materials used in manufacturing

carriage bolts. While traditional carriage bolts were made of iron, modern

variants are often crafted from steel, stainless steel, or other alloys. These

materials enhance the bolts' strength, corrosion resistance, and overall

longevity, making them suitable for diverse environments and applications.

To meet the demands

of specific industries, manufacturers began coating carriage bolts with

protective finishes. These coatings, such as zinc plating or galvanization,

provide an additional layer of defense against corrosion, ensuring that the

bolts remain in pristine condition even when exposed to harsh environmental

conditions.

Varied Designs for Specialized Uses

The evolution of carriage bolts also led to the development of

specialized designs to cater to unique applications. Some variants feature a

flange under the head, providing a larger load-bearing surface. Others may

incorporate serrations on the underside of the head to prevent loosening over

time. These innovations showcase the adaptability of carriage bolts, allowing

them to excel in a wide range of situations.

Carriage Bolt Suppliers: Navigating the Market

In the intricate web of construction and manufacturing, the role of carriage bolts is inseparable from the reliability of their suppliers. "CarriageBolt Suppliers: Navigating the Market" explores the critical considerations and nuances involved in selecting the right partners in this essential facet of industry.

Choosing

Reliability: The journey begins with the pivotal decision of selecting a supplier,

emphasizing the need for trustworthiness and consistent quality.

Industry Standards: Reputable

suppliers adhere to stringent industry standards, assuring customers of the

reliability and performance of their carriage bolts.

Customization

Flexibility: The ability to cater to specific needs, whether it's material

preferences or unique design requirements, adds a layer of versatility to

supplier options.

Navigating the

market for carriage bolt suppliers demands a keen understanding of the supplier

landscape, an appreciation for adherence to standards, and a focus on

customized solutions. Join us as we embark on a journey through the intricacies

of selecting the right carriage bolt supplier, ensuring the seamless

integration of these essential fasteners into the vast tapestry of construction

and manufacturing.

Choosing the Right Supplier

Selecting the right carriage bolt supplier is a critical decision that

profoundly impacts the success and reliability of construction projects. In a

market flooded with options, making an informed choice requires careful

consideration of various factors. Let's delve into the key aspects to

contemplate when choosing a carriage bolt supplier:

1.

Quality Assurance:

·

Ensure the supplier adheres to stringent quality standards.

·

Verify the quality control measures in place during the manufacturing

process.

2.

Material Selection:

·

Evaluate the range of materials offered by the supplier.

·

Consider the specific requirements of your project and choose a supplier

with suitable material options.

3.

Customization Capabilities:

·

Assess the supplier's ability to provide customized carriage bolts.

·

Check if they can accommodate unique specifications and tailor products

to project requirements.

4.

Reliability and Reputation:

·

Investigate the supplier's track record and reputation in the industry.

·

Seek testimonials or reviews from previous clients to gauge their

reliability.

5.

Cost-Effectiveness:

·

Compare pricing structures among different suppliers.

·

Balance cost considerations with the quality of the products and

services offered.

6.

Inventory and Availability:

·

Ensure the supplier maintains a consistent inventory.

·

Check for their ability to meet project deadlines and provide timely

deliveries.

7.

Customer Support:

·

Evaluate the level of customer support provided by the supplier.

·

A responsive and communicative supplier can be crucial in addressing

concerns or making adjustments during the project.

8.

Compliance with Standards:

·

Confirm that the supplier adheres to industry standards and regulations.

·

Compliance ensures that the carriage bolts meet safety and performance

criteria.

9.

Global Reach:

·

Consider whether the supplier has a global reach.

·

International suppliers may offer diverse perspectives, materials, and

cost advantages.

Evaluating Quality and Certification

Reliable carriage bolt suppliers adhere to industry standards and may

possess certifications attesting to the quality of their products. Before

making a purchase, it is advisable to verify the supplier's compliance with

relevant standards and inquire about any certifications they may hold. This diligence

ensures that the carriage bolts meet the necessary specifications for your

specific application.

Customization Options

The best carriage bolt suppliers recognize the diverse needs of their

customers and may offer customization options. Whether it's a specific

material, coating, or unique design requirements, working with a supplier who

can accommodate customization ensures that you get bolts tailored to your exact

specifications. This flexibility is particularly valuable for industries with

specialized demands.

Read Also: Prime Bolt Solutions: Engineering Excellence in U Bolt Production

Future Trends: Innovations in Carriage Bolt Technology

In the dynamic landscape of construction and manufacturing, even seemingly humble components like carriage bolts are not immune to the tide of innovation. The future of carriage bolt technology promises a fascinating intersection of efficiency, durability, and sustainability. As industries evolve and demands for enhanced performance grow, manufacturers are delving into novel approaches to design and materials.

One prominent trend

in carriage bolt innovation revolves around materials engineering. Traditional

materials like steel are being reevaluated and replaced with advanced alloys

and composites, offering a delicate balance between strength and weight. The

push towards lightweight materials is not only driven by the need for more

fuel-efficient transportation but also by a broader commitment to reduce the

ecological footprint of production processes.

Moreover, the

integration of smart technologies into carriage bolts is a futuristic leap in

itself. From embedded sensors monitoring stress and tension levels to the

implementation of self-healing materials, the aim is to enhance the bolts'

predictive maintenance capabilities, minimizing downtime and increasing overall

system reliability. This shift towards intelligent bolts aligns with the

broader trends of Industry 4.0, where interconnected devices and data-driven

insights redefine traditional manufacturing paradigms.

Environmental

sustainability is another key driver shaping the future of carriage bolt

technology. As the global focus on eco-friendly practices intensifies,

manufacturers are exploring innovative materials with lower environmental

impact. Additionally, the design of bolts with recyclability in mind is

becoming a priority, ensuring that end-of-life disposal processes are more

environmentally responsible.

Smart Bolting Solutions

As industries continue to advance, so does the technology surrounding

fasteners. Smart bolting solutions, equipped with sensors and monitoring

capabilities, are emerging as a potential trend in the world of carriage bolts.

These intelligent bolts can provide real-time data on factors such as tension,

temperature, and torque, enhancing the efficiency and safety of various

applications.

Sustainable Materials and Practices

The growing emphasis on sustainability is influencing the materials used

in manufacturing carriage bolts. Suppliers and manufacturers are exploring

eco-friendly materials and adopting sustainable practices to minimize the

environmental impact of production. This shift aligns with the broader movement

towards greener and more responsible manufacturing processes.

Conclusion

The carriage bolt, born out of necessity in the 19th century, has stood the test of time and adapted to the evolving needs of industries. From its humble beginnings securing wooden carriages to its integral role in modern machinery and infrastructure, the carriage bolt has witnessed and influenced centuries of progress. As we continue to bolt into the future, it's essential to appreciate the historical journey of this unassuming yet indispensable fastener. Choosing reputable carriage bolt suppliers and dome nut Suppliers ensures that this journey remains one of reliability, strength, and innovation, embodying the enduring legacy of the carriage bolt in the tapestry of industrial history.

Comments

Post a Comment